Existing processes in wheat dough processing are often artisanal. This leads to further strong fluctuations in product quality. Extensive automation, in the long term self-regulating processes, can reduce these fluctuations. It is important that parameters and target values recognized as important, first and foremost product quality, are continuously monitored.

The project focuses on industrial application and aims at results that are of high practical relevance. The data collected in the project and the models based on it are intended to provide a better understanding of the complex interactions in wheat dough processing.

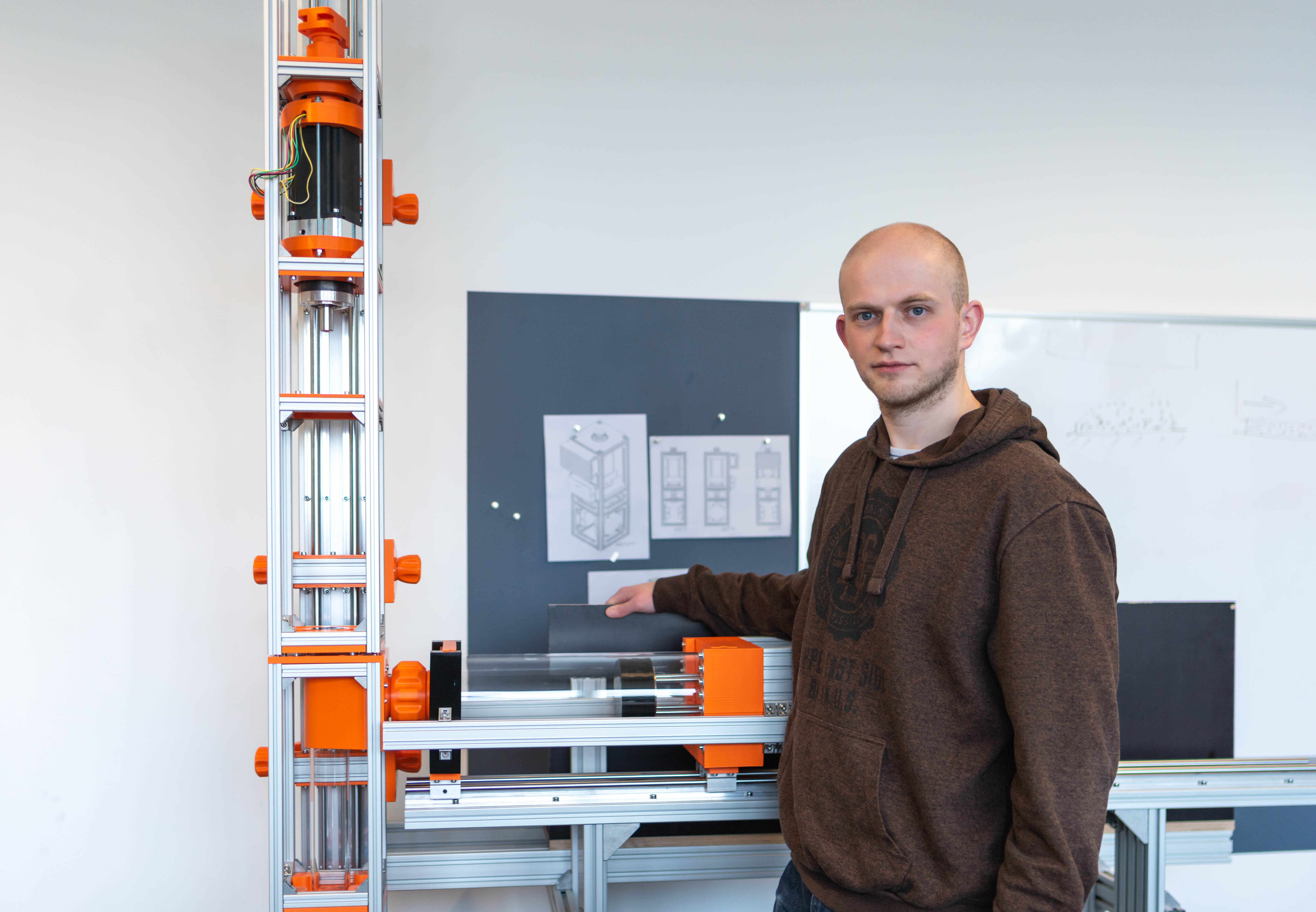

The aim is to use inline-capable measurement technology to record raw material and intermediate product properties in wheat dough processing already during the production process and to evaluate them in real time. This minimizes waste, conserves resources and prevents food wastage.

Project leaders:

Prof. Dr. Ulrich Müller, Prof. Dr. Volker Lohweg, Prof. Dr. Björn Frahm

Project partners: